PHOTOMETRIC STEREO

Sample Application: Threaded Part Inspection

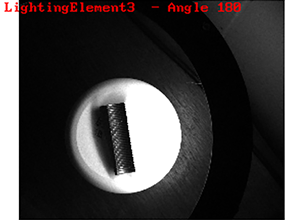

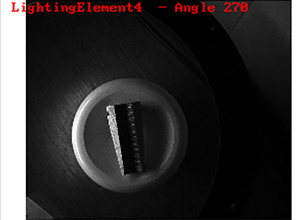

The following threaded metallic part presents another challenge for standard vision light and camera configurations. The varying heights of the object’s threads create significant shadowing, making it very difficult to visually inspect for defects. The metallic surface also presents a challenge with unwanted specular reflections.

Similar with the bottle inspection, we independently control the quadrants of a DF198-115 MicroBriteTM Diffuse Ring Light with the DCS-400E Quad Controller to illuminate the threaded part from four directions.

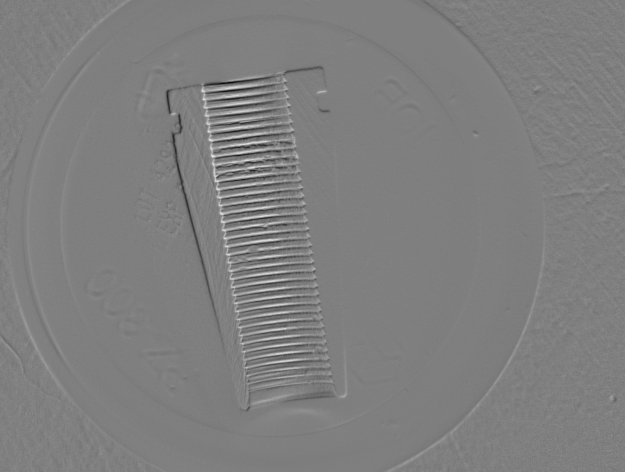

Final Processed Image

The input images in highlight the inspection challenges created by the shadowing and reflections of the part’s 3D surface characteristics. However, by processing the images in the Matrox Design Assistant and Imaging Library, the final flattened shape image removes the specular reflections and severe shadowing. This results in an image more easily inspected for damaged threads or other imperfections.

Ai Products Featured in the Sample Application

DF198-115 MicroBrite™ Diffuse Ring Light

DCS-400E Quad Controller