The Machine Vision Industry has had an interesting and critical role to play in the overall development of the LED Lighting Market. Most people are unaware that the first commercially available LED lights were made exclusively for the Machine Vision Market. This is easy to understand when you realize that the first LEDs with enough power to produce an illumination device were only available in monochromatic red (660nm).

Prior to their development as a machine vision light source, LEDs were only useful as indicator lamps, replacing miniature incandescent bulbs in electronic products.

As a monochromatic source with negligible output power, the earliest illuminators were only effective for use with monochromatic sensors at short working distances. This made them an ideal fit for many machine vision applications, especially considering their reliable, photonically stable output, as well as their ability to be turned on and off in rapid succession without degradation. In addition, a low duty cycle imaging process (short exposure time/single inspection event) lent itself to “overdriving” the LED with up to 30X the nominal, constant rated current. Other light sources at the time varied in performance over their relatively short life spans, producing inaccurate imaging results while requiring increased maintenance.

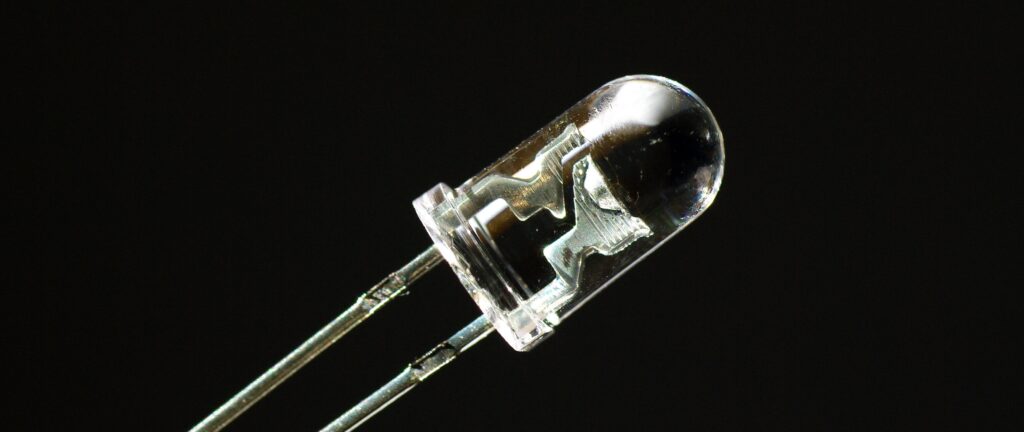

The first commercially available LED lights, developed by Advanced illumination (Ai) in 1993, utilized a diode and reflector cavity molded into a solid epoxy, dual inline package (DIP).

Figure 1 – Close up image of a dual inline package LED (image to the left).

This type of LED package had the advantage of being inexpensive, due to its volume application as an indicator lamp, while also providing the very efficient delivery of light with it’s molded-in lens. The lenses came in a variety of shapes, producing a wide selection of beam angles, some with a Full Width Half Max (FWHM) angle of as little as 6°.

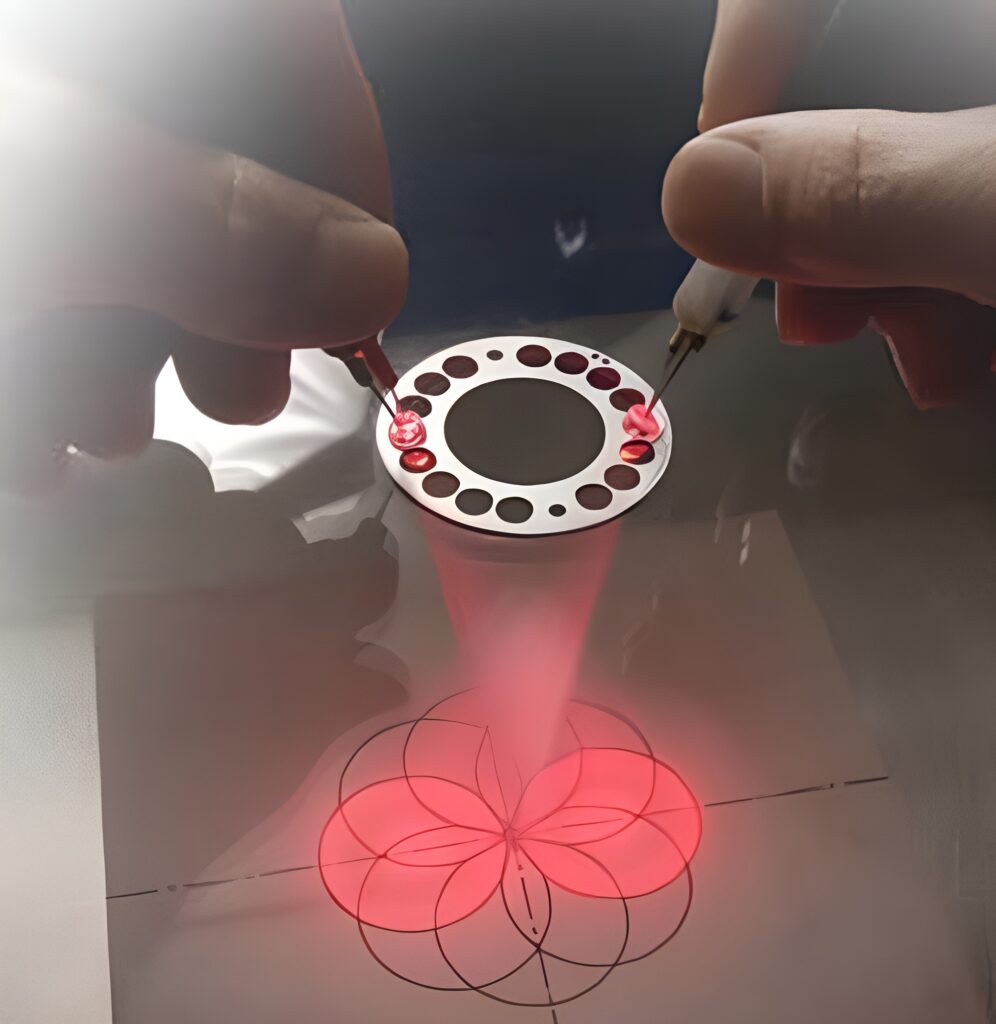

To produce a viable illuminator at this early stage, Ai developed a patented process to concentrate the light from a number of these LEDs, aiming them at a relatively small field of view, appropriate for machine vision applications at that time. As mentioned earlier, these LEDs could also be “overdriven” considerably which further improved the viability of these very first LED lights. This need for high light concentration led to Ai’s invention of the first LED overdrive strobe controller in 1994.

Figure 2 and 3 – Advanced illumination’s first patented LED aiming process (image to the left). First LED overdrive strobe controller, developed by Advanced illumination (image to the right).

Another pioneer in the development of LED lighting, ProPhotonix (formerly CorkOpt), established in 1994, utilized Chip on Board (COB) technology to produce lighting, also for the Machine Vision Market. This early COB process consisted of the same 660nm diodes bonded directly to a sputtered silver conduction layer on a substrate of silicon crystal.

While the aiming of LEDs and the use of overdrive strobe electronics, as well as the early COB implementations were not feasible for the General LED Lighting Market to come, it drew attention to the LED as a feasible lighting system component. And with the development and increasing power of blue LEDs later in the decade, as well as the discovery that common Yttrium Aluminum Garnet (YAG) television tube phosphors could down-convert blue wavelengths into broadband “white” emissions, the groundwork was laid for the solid-state lighting revolution.

It wasn’t until a third LED “package” style was developed, in particular, the Surface Mounted (SM) Philips/Agilent LumiLed Luxeon, that general-use, solid-state lighting would be feasible for the Commercial and Consumer Lighting Markets.

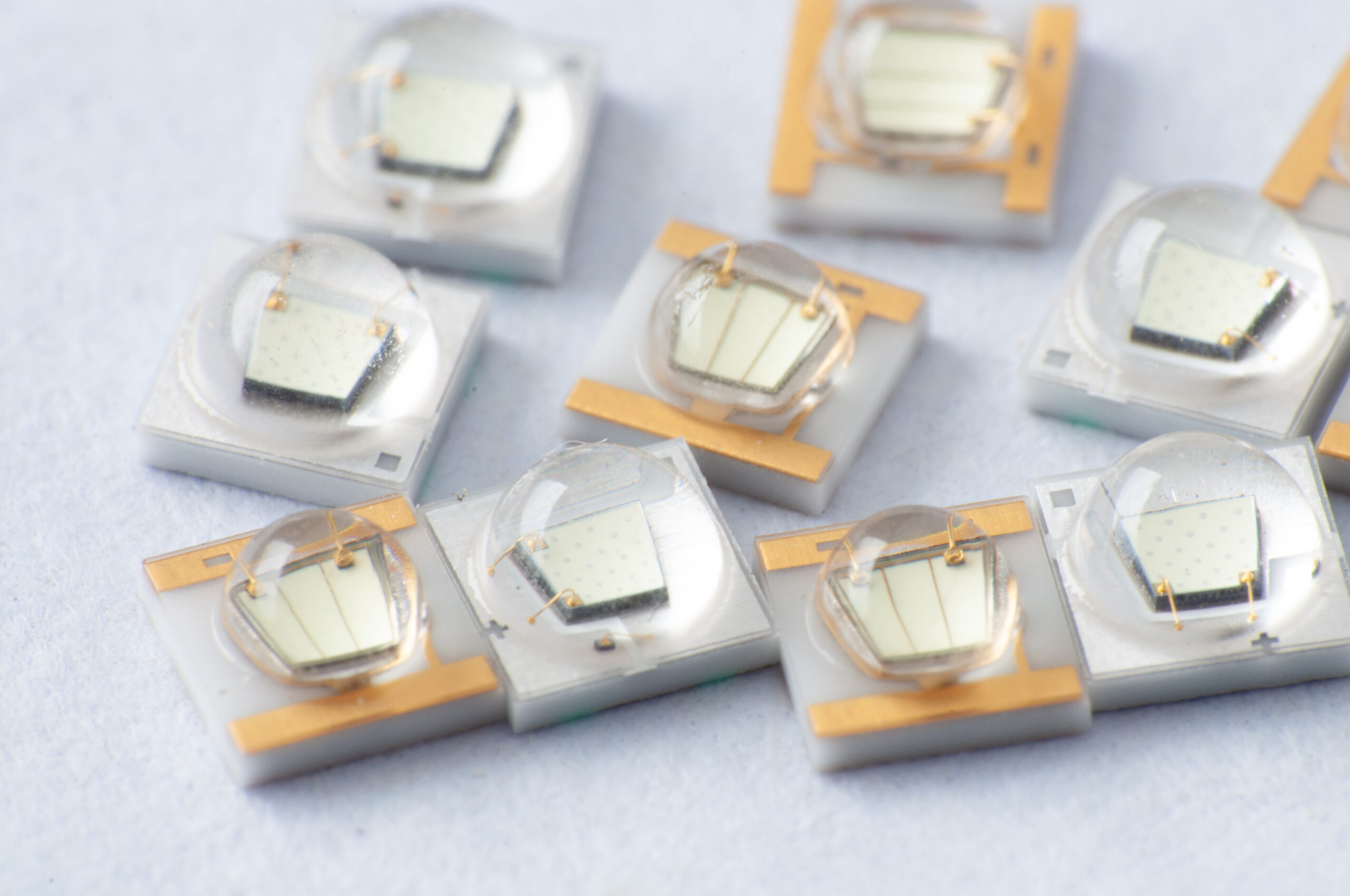

Figure 4 – First surface mount LED, the Luxeon 1-Watt Emitter (image to the right). Image courtesy of Lumileds.

Machine vision lighting devices weren’t the first to utilize these SM LEDs, however they played an incredibly important role in driving the application reach within the machine vision field, very early on. These LEDs utilized a metal “slug” as a thermal bridge directly under the die, down to the PCB. This arrangement was revolutionary at the time and very efficient, albeit a bit unwieldly from a manufacturing standpoint. The SM LEDs common today generally utilize an electrically isolating, ceramic substrate, greatly simplifying assembly. These Surface Mount devices, as well as the latest generation of COB technology have truly revolutionized the current General Lighting Market.

Advanced illumination and ProPhotonix, our sister company under the Exaktera umbrella, both played pioneering roles in the development of practical lighting solutions for the Machine Vision Market. In turn, we like to think we had some small role to play in the wider acceptance and implementation of the LED lighting we all use today.